Laser Alignment

Machines operating in perfect alignment run at their most efficient. Misaligned shafts are recognized as one of the greatest contributors to plant breakdowns, due to the increased forces placed on bearing, mechanical seals, internal components and motor drives.

Rotating machines are prone to misalignment. Correctly aligned and regularly controlled machines significantly reduce operating and maintenance costs. Conventional methods for shaft alignment, such as straightedge, thickness gage or dial gage, are very time consuming. The quality of the results also highly depends on the experience of the operator.

Our laser measuring devices use unique state-of-the-art technology to ensure maximum precision and user-friendly alignment of shafts.

Precise alignment pays off in many ways:

- Reduce power consumption

- Decrease wear on bearings, seals, shafts and couplings

- Avoid overheating of bearings and couplings

- Reduce vibrations in shafts and foundation bolts

- Significantly reduce damage to shafts and foundation bolts.

ACMEI provides onsite Laser Shaft Alignment field services for horizontal alignment of pumps, drives, motors & gearboxes.

- Direct drive Fans

- Motor-driven Pumps

- Gearboxes

- Compressors

- Turbines

- Transfer boxes

- Propeller shafts

- Couplings

- Conveyors

- Generators

- Mixers

A modern Laser Shaft Alignment system utilizes laser-based technology to ensure that the shafts are coupled together along a perfect rotational centerline.

A Laser Shaft Alignment System offers precision alignment of shafts to within hundredths of a millimeter. The latest Shaft Alignment System manufactured by Easy Laser offers sophisticated laser alignment technology that is fast and easy to operate in the field.

Industrial Applications for Laser Shaft Alignment

Laser Shaft Alignment offers benefits in any industry where rotating equipment applications are deployed:

- Alignment Shafts

- Alignment Measurement

- Alignment Shims

- Alignment Systems

- Bearing Failure

- Coupling Alignment

- Drive Shaft Alignment

- Fixturlaser

- Foundation Settlement

- Gearbox Alignment

- Horizontal Alignment

- Industrial Alignment

- Laser Alignment

- Laser Alignment System

- Motor Alignment

- Prop Shaft Alignment

- Pump Alignmentt

- Roll Alignment

- Vertical Alignment

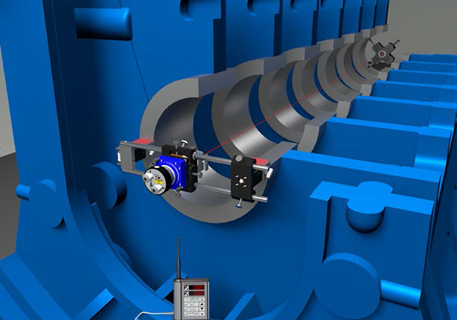

Bore Alignment

ACMEI makes the most accurate, easy to use and portable bore alignment laser on the market today. Our patented self-centering bore adapters eliminate the need to take 2 measurements (0 degrees & 180 degrees) for each bore, a standard practice to take out bore diameter changes. This makes bore alignment extremely easy and very fast!

With a variety of target options, such as self-centering, see-through, 2-axis and 4-axis, Hamar's bore alignment lasers have a solution for you. Windows-based Bore9 software can analyze the alignment data or it can be simply displayed on hand-held readouts. As with all of ACMEI's products, the data is live, so if your bore is out of alignment, the laser can be used to bring it into tolerance.

Tightly controlled tolerances and innovative designs mean fast setups and easy fixturing. To give an example of the measuring speed of this laser system, a 10-foot cylinder bore can be measured for straightness every three inches in 10 minutes or less, including setup.

Applications for the laser bore alignment system include bore straightness checks on individual parts, boring-bar bearing alignment, crank-shaft bore alignment, extruder barrel alignment, tail-rotor bearing alignment on helicopters, bar-turning machines, stern tubes in ship building, aluminum can-making machinery and hinge-line alignment for commercial jets. There are very few bore alignment applications that we have not seen in the last 35 years, so even if you do not see your specific application listed here, please call and we will work with you to solve your alignment problems.

Power Generations

The most common method of turbine alignment is the tight wire. Although tight wire has produced good results for many years, it is increasingly becoming outdated. It takes too long to set up, is subject to vibration, which limits other work during alignment and is subject to catenary sag and other environmental influences. With power company consolidation and competitive power markets, shorter outages and more efficient turbines are critical to industry profitability.

The combination of the L-705 Turbine Alignment System, the L-740 Split-Joint Measuring System and the S-680 Coupling Alignment Systems create a powerful tool kit to significantly reduce turbine outages and increase efficiency. To give an example of increased efficiency, an L-705 customer told us that a turbine took 10 minutes to stop rotating after shutdown prior to laser alignment and 30 minutes after laser alignment!

There are 2 basic types of lasers:

Straight-Line Laser Systems - designed for steam turbine bore and shaft alignment applications.

Continuously Rotating Laser Systems - designed for split or horizontal-joint flatness measuring applications.

Our continuously rotating laser systems come in 2 accuracy grades: the L-730 Precision Series and the L-740 Ultra-Precision Series. Each series offers 4 different laser systems with single, dual and triple plane versions. The L-730 Series is designed for those with accuracies needs of 0.00012"/ft (0.01 mm/M) or higher and the L-740 Series is for those with accuracy needs of 0.00002"/ft (0.0017 mm/M) or higher.